my MOST COMPLEX PROJECT

This rocket was built and funded entirely by myself. It is the culmination of my engineering knowledge. It was flown a total of 4 times:

Baby Come Back 3 Flight #1 (success): Pence, IN - 2200 ft, for Level 2 certification

Baby Come Back 3 Flight #2 (success): Pence, IN - 11,000 ft, with custom L840 propellant

Baby Come Back 4 Flight #3 (success): Mojave, CA - 18,004 ft with custom M1200 propellant and upgraded data logging and repainted

Baby Come Back 5 Flight #4 (success): Pence, IN - 13,400 ft on Aerotech L1390G, with live telemetry downlink

BABY COME BACK 5 - live telemetry

I launched Baby Come Back 5 while introducing rockets to middle/high schoolers from the Minority Engineering Program Indianapolis (MEPI).

Sharing my passion for engineering has always been very important to me, and seeing the enthusiasm and excitement around the students reminded me of just that.

The rocket flew to 13,640 ft, reaching Mach 1.6 as it flew through the clouds. The new downlink system for live telemetry worked flawlessly, echoing the rocket's real-time altitude, and parachute deployment confirmations leading to a successful recovery.

BABY COME BACK 4 - MOJAVE DESERT LAUNCH

After upgrading the data-logger and repainting Baby Come Back 3 white for thermal management., I packed it all up in a suitcase and flew out to California.

There, I met up with Alex Patrus, who had brewed up a custom M1200 for the flight. There, Baby Come Back 4 was born

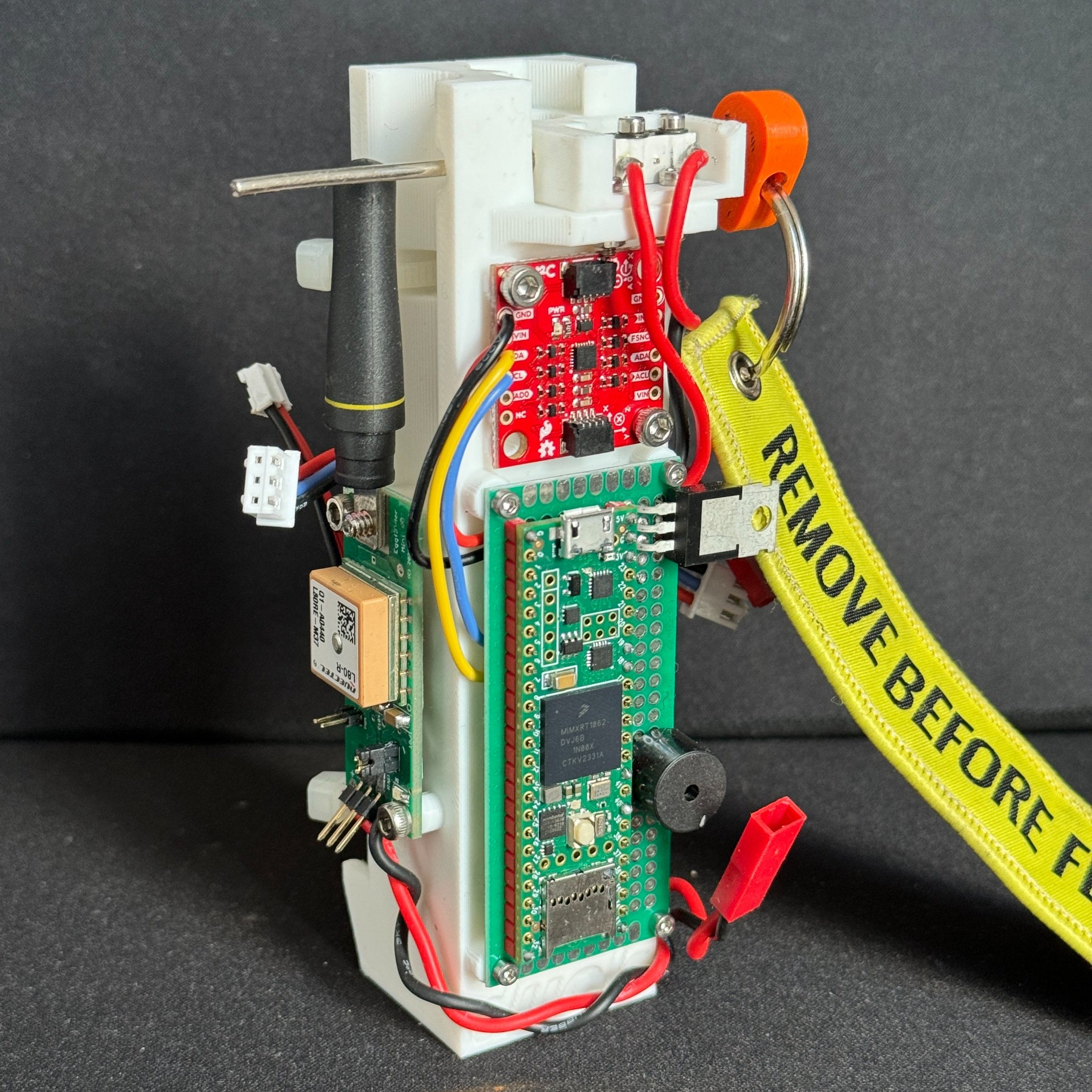

Updated data logger with 2x 6DoF IMUs, barometer and GPS transmitter

What’s different?

2x 6DoF IMU

Barometric sensor

M1200 Custom APCP propellant: 5860 Ns of Impulse

18,000 feet MSL

Mach 1.6

More plots, data and results coming soon!

BABY COME BACK 3:

BABY COME BACK 3 - L2/L3 Rocket

LENGTH: 88.5in

DIAMETER: 3.215 in

MAX VELOCITY: Mach 1.23

ALTITUDE: 11,510 ft MSL

PROPULSION: Custom APCP L840

Goals:

Obtain Level 2 certification

Reach 10,000 ft MSL

Achieve supersonic flight

Validate nylon-12 fin binder

Full recovery

(flight results coming soon!)

DESIGN WALKTHROUGH:

The motor is a custom propellant developed by Harry Amadeo (YouTube) named Fatboy.

Motor Testing by Harry Amadeo:

L840 Static fire with data overlay animated in MATLAB and integrated in Premiere Pro

The expected average thrust was ~1200N, the static fire resulted in only 840N. A higher thrust is desired for a higher thrust to weight ratio. As such, the propellant grains for the flight motor were cut in half thereby increasing total surface area for burning by 14%.

A pressure transducer, along with an EasyMotor - a motor data logger by Altus Metrum - is added at the forward bulkhead of the motor casing to measure the actual thrust curve of the flight motor with the increased surface area.

9DoF data logging

Camera shroud study:

To estimate the impact of the camera shroud on the drag coefficient and maximum altitude, data from an OpenRocket simulation was exported and plotted in MATLAB.

From these plots, it is clear that the addition of the camera shroud does negatively impact the drag coefficient and maximum altitude. However, a 400-feet deficit in maximum altitude is small enough to justify the addition of onboard footage.

What is interesting about the drag coefficient vs mach number plot is the behavior near the transonic region. We expect the drag coefficient to continue to increase until mach = 1, but the OpenRocket data depicts a brief period of decrease around mach = 1. This may be explained by OpenRocket’s known inaccuracies at supersonic and transonic regimes.

MANUFACTURING:

Full rocket stack up

Fin beveling jig

Assembled fin can

Fins cut and beveled

Test of 0.25mm bent sheet aluminum leading edge caps

Avionics bay and motor coupler

Machined aluminum nosecone tip