THE MITES COMPETITION

The Michigan Industrial Technology Education Society (MITES) competition is an annual convention in which students from all around Michigan submit entries based on their chosen category. More information on the 2019 competition and categories here.

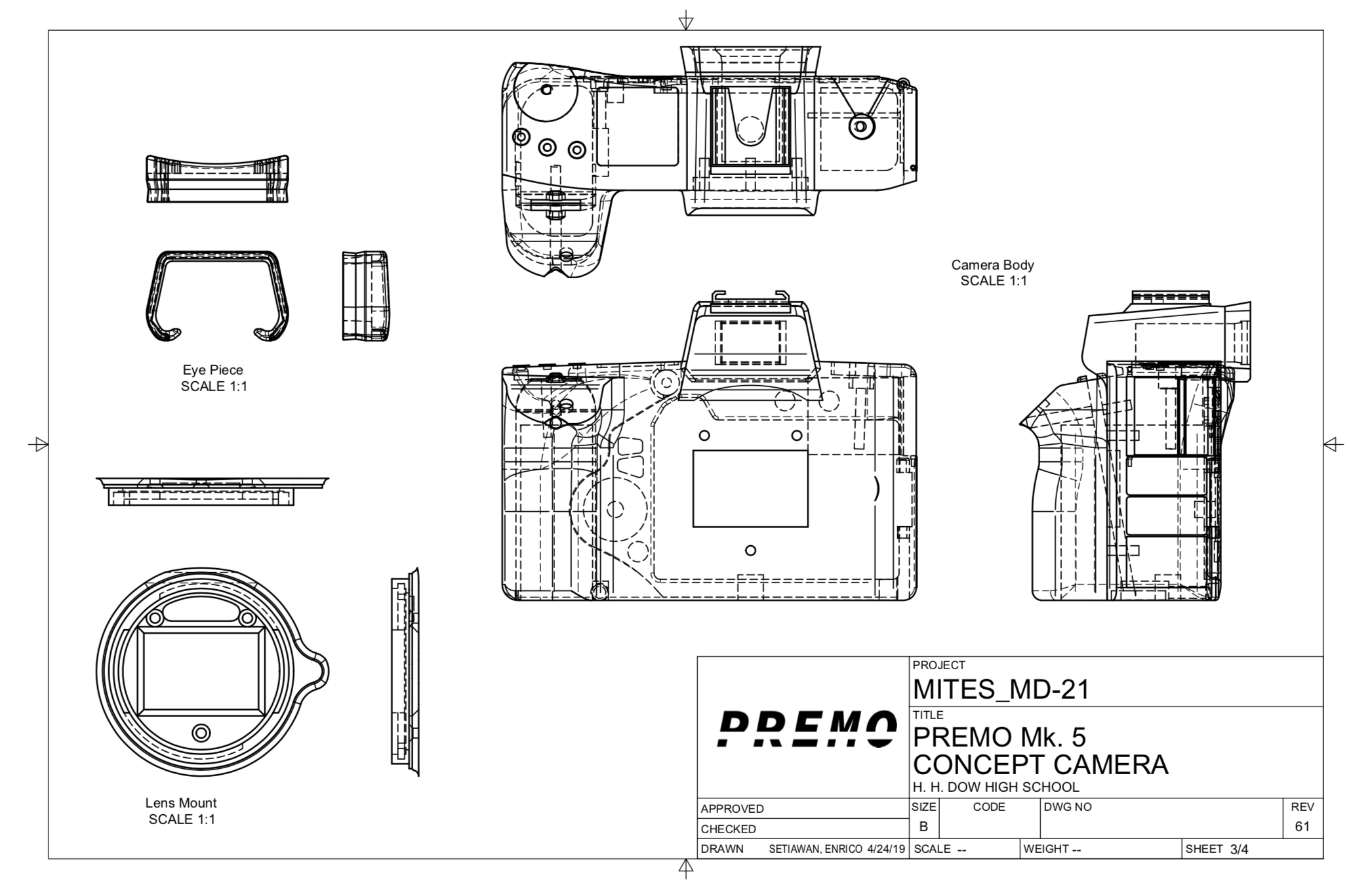

I decided to enter the MD-21 category - rapid prototyping with CAD assembly (multiple parts) and 3D printing.

The main challenge for this category was that the use of adhesives was not allowed. The parts had to either be secured by standardised hardware, or designed to be a snap fit. Although I did take advantage of a few M3 screws, some parts were just far too small for common hardware. These parts then had to be snap fitted which involves extremely tight tolerances which is always a challenge with 3D printing. The amount of iterations with these snap fit parts totalled to almost half a kilogram of plastic. Another solution to “weld” parts together was to use a heat gun to melt the surface layers of two parts, effectively plastic welding them together.

My efforts paid off, winning First Place in the state.

As of the beginning of the 2019-2018 school year, my Camera is now being used as an example to teach CAD classes.

3D printed camera (right)

It took five prototypes to perfect the ergonomics of the grip and proportions

Moveable parts

One of the distinguishing features of the 3D printed model was the moveable parts.

Working flip out screen

Lock-release mechanism for lens and lens hood

Working dials

Openable battery door (bottom)

Openable SD card door

Dimensionally correct and working tripod mount (bottom)

The Model

Explore the 3D model below: